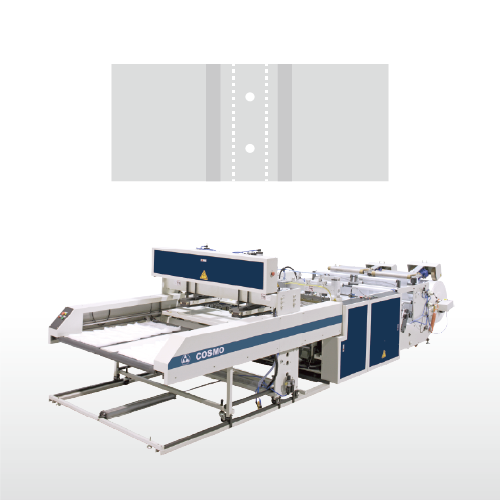

Zipper Bag Making Machine

Categories : Plastic Bag Making Machines

World Steel is a manufacturer of Zip Lock Bag Making Machines. The machines use the latest technology offering advanced performance and versatility that facilitate easy installation, setup, operation and maintenance. These machines are ideal for producing high quality ziplock bags at an excellent cost efficiency. EFFICIENT ZIP LOCK BAG MAKING MACHINE:HIGH CAPACITY AT 120 BAG/MIN The Automatic Zipper Bag Machine converts a tubular roll of pp material with clip chain structure into a side seal bag, no need to purchase additional zippers. The machine is capable of running at 120 bags / minute. This saves cost, space and labor. AUTOMATIC ZIPPER BAG MACHINE FOR PP FILM Our Automatic Zipper Bag Making Machine can be used for producing a high quality side sealed zipper bag from PP materials.

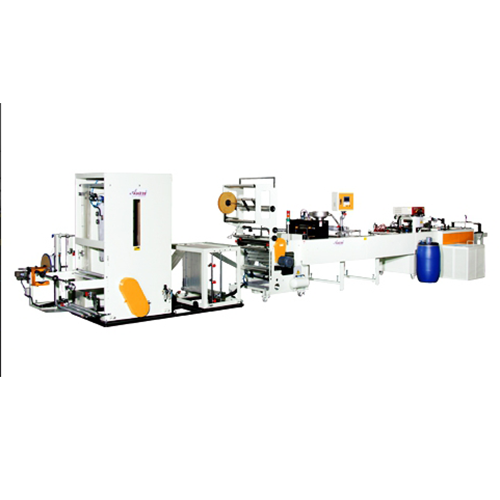

Fully Automatic High Speed 2 Lines Saddle Bag & Wicket Bag Making Machine SSD-600-L2

Categories : Plastic Bag Making Machines

Computer control over the entire process From film roll to final pruduct, one process flow Automatically stop when running out of film / film feeding blocks or jam High-productivity performace saves time and labor

Automatic Slider Taper Bag Making Machine

Categories : Plastic Bag Making Machines

- Suitable for LDPE, PP OPP CPP BOPP and EVA. - The unit begins from triangular folding unit with EPC, Tension control unit with automatic - calculation, zipper attachment, automatic slider inserter, gang puncher, ultrasonic stamping, precise triangular sealing, automatic scrape remove system, collector to wicketer windmill fully automatic in one process. - Servo Driven is fast and precise. - Servo motor cutting Control System. - The unit uses PLC Control System.

Hydro Dipping Machine - Semi-Automatic - YHT223AXF

Categories : Hydro Dipping Spraying Equipment

Dipping Tank + Auto Film Layer + Auto Spray System Dipping Tank 3 meters length. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. YHT-223A2XF This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. This system can memorize multiple sets of different processes. YHT-223A2XF is perfect for large product and medium quantities of production/day

Floor Mounted Auto Vacuum Loader

Categories : Loaders and Conveyors

The separated design of a blower and a suction hopper with mighty horsepower is suitable for long distance conveying. The flexible combination of one blower with one suction hopper up to four suction hoppers can help you to save space and equipment investment cost. That also keeps your resin away the pollution and extend suction points easily for future need. TA series Easy use by a quiet and powerful induction motor. The motor cabinet can be placed on the floor for convenient operation and the suction hopper on the hopper dryer for easy installation. TB series Use the same commutator motor as the BC series, and separate motor cabinet and suction hopper design as the TA and TC series. Combine the advantages of the hopper mounted and floor mounted loaders. TC series The blowers are belt-driven that are the best choice for silent operation. Patented Optional Parts Vortex Cyclone (VC): Works with any auto loaders to stop the regrinded resin from discharging to the surrounding area. Filter Set: s optional equipment from YANN BANG is perfect for dust-free of indoor working place. To do the filter routine maintenance is so easy without dirtying your hands and place. Unload the filter set without opening the cover until move to the please you want to clean. Auto Dust Cleaner: Saves your time and labor. No need to clean your filter anymore. The Auto Dust Cleaner is designed to install upon the filter of the loader. Set the timer and it cleans your filter routinely.

2-in-1 Conveying Dryer (CD)

Categories : Dryers and Dehumidifiers For Plastic Materials

Hopper dryer combine vacuum loader is perfect to move anywhere for your need. A stainless insulated hopper dryer with dual layer to help drying better and faster. Save more energy and increase higher efficiency. A vacuum loader automatically supplies dried resin to avoid the shortage of material during production. Installed pipe-clean device (Taiwan Pat:M299801) and closed-loop can prevent the moisture return, static electricity and resin pollution inside the pipe for better quality. Patented Heat-recycler (Taiwan Pat:226245;China Pat:01258213.1) can save your energy, increase drying and decrease the pollution of hot air and dust. Installed weekly timer and safety protectors can save your labor cost and protect operators in better working environment. Only one control unit is convenient for you to monitor all suction points. Able to extend suction points up to four as 1 to 4 small central conveying system to supply resin for raw material areas and numerous molding machines. Save your equipment cost and space without extra spend.

Hopper Mounted Auto Vacuum Loader

Categories : Loaders and Conveyors

BC series Use high speed, powerful, single phase commutator motor and is the smallest and the most economical loader in our range. Compact size, light weight, low noise, easy operation and installation, suit to convey one kind of resin or material, can install upon a hopper dryer or molding machine directly. It is ideal for small machines. BL series Easy use by the three phase powerful induction motor. Suitable for medium to large size machines, such as extrusion molding machine.

Twin Shaft Shredder (Kroko Twin Series)

Categories : Plastic Shredders

Intelligent control system The program system monitoring the shredding status and allows automatically reverse and forward motion to keep most stability while creating best production. High radial loads with high efficiency and great stability The professionally designed shaft and blades are made with high wear-resistant steel and processed by heat-treatment to increase the service life. It can withstand higher radial load and create higher efficiency while keep the best stability.

FP-X Turret Rewind Shrink Sleeve Seaming Machine

Categories : Shrink Sleeve Machinery

HCI's new generation of FP-X high-speed turret rewind shrink sleeve seaming machines which meets the requirement of high-speed production, automatic roll-changing and online inspection. With rewind auto splicing, In-Line layflat and Solvent Auto Detection system to have seaming & doctoring process two-in-one. Together with new developed precise needle type solvent supply system is highly increasing the stability of solvent application, forms and seals on shrink sleeve making process.

Automatic Packing Tape Slitting & Rewinding Machine

Categories : Slitters and Rewinders

Application: BOPP tape, cellophane tape, masking tape… (according to customer informed material) yicheen

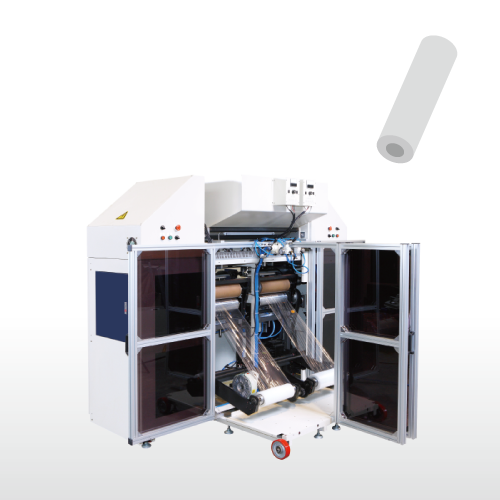

Paper Core cutter

Categories : Cutting Machines

Application:Double side adhesive tape, Paper core, PVC, Rubber, leather, foam… etc. roll tube yicheen

Fully Automatic High Speed 4 Spindles 2 Lines Stretch Film Re-Winder (Industrial Type) / SIWCR-500-L2

Categories : Slitters and Rewinders

-Computer control over the entire process -From film roll to final pruduct, one process flow -Automatically core changing system